Clearance

Function of Clearance:

Bearing clearances have a relatively great influence on the bearing life, revolution precision, vibration, noise, temperature, friction resistance etc. The main function of clearance includes:

Guarantee the flexibility of bearing revolution

Adjust the space of bearing load

Guarantee the bearing gets the correct contact angle (angular contact ball bearing)

Reduce the friction between the parts

Diminish or eliminate the influence for bearing running performance due to the dimension deviation resulted from the heat expansion, interference fit of parts

Helpful for the form of lubricating oil film

Convenience for the inspection of bearing precision

Selection of Clearance:

In order to guarantee the good state of bearing running, it is necessary to choose suitable bearing clearance. To select bearing clearance should pay attention to several questions as below:

The internal dimension alternation of bearing under interference fit

The dimension variation resulted from the temperature alternation when the bearing is running

The internal dimension deviation due to the different material expansion factors of axis or bearing blocks

In the actual operation, the general rules of selecting clearance are:

The working clearance of ball bearing should be zero, or have slight preload

Cylindrical roller bearing and spherical roller bearing must have certain working clearance

Taper roller bearing should usually have certain clearance, but if there is requirement for bearing rigidity, should be imposed on certain preload

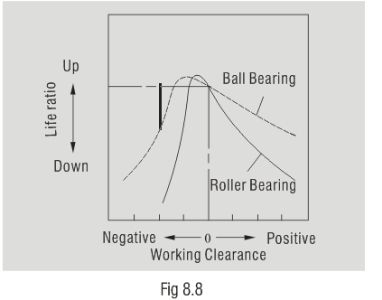

Theoretically, when bearing working clearance is slightly negative (with a certain preload), the fatigue life of bearing is the longest, refer to Fig. 8.8. But the ideal state is difficult to keep due to many non-predicative factors, it could have the possibility to realize after iterative practice and adjust. It shows in this fig, when the negative clearance of bearing becomes large further, the bearing fatigue life will obviously decline. This is a reliable method to select a larger working clearance value (over zero).

In GB/T4604

The basic clearance group should be the priority selection for the bearings in normal working conditions. The basic clearance group should be the priority selection for the bearings in normal working conditions refer to:

·Inner ring rotating, inner ring and axis is assembled with interference fit

·The load of bearing P≤0.1Cr

·The speed of bearing is approximately less than 50% of its limiting speed

·Sufficient lubrication

For some bearings under the certain working condition, it should select different groups of bearing clearance according to their specific working condition. In order to lower the noise of motor bearings, the selected bearing clearance could be relatively smaller. In the situation of high rotating precision it should also select smaller clearance. However, the larger group of clearance should be selected for the high speed bearing or rolling mill bearings to reduce the rotating friction and lower the temperature of bearing. When the working temperature of bearing is higher, then a larger clearance should be selected.

Usually, this would mainly control the radial clearance of bearing, for three-point, four-point contact bearing and double-row, four-row taper roller bearing etc., it should control the axial clearance of bearing during the process of production.

The original clearance of bearing was mostly “errorred” due to the influence of the factor of heat during the assembling and working process etc., so the working clearance of bearing is usually smaller than original and assembling clearance.

Estimated according to the experience:

After assembling the bearing, the raceway of inner ring will expand due to the interference fit, the original clearance will reduce accordingly, the reduction is approximately 70%~80% of the interference fit value. In the same way, if the outer ring is interference fit, the raceway will reduce, the original clearance is also reduce.

During the rotating of bearing, the temperature difference will emerge between the inner ring and outer ring, the temperature of inner ring (inner ring rotating) is usually higher than that of outer ring (outer ring is static), the expansion of inner ring due to the heat will result in the reduction of clearance. The reduction could be estimated according to the following formula:

ΔGt≈α·Δt·F

Where

ΔGt-The reduction of radial clearance resulted from the heat difference between the two rings, mm

α-The linear expansion factor of bearing steel 12.5×10-6, 1/℃

Δt-The temperature difference between inner and outer rings, ℃

F-The diameter of outer raceway, mm

The working clearance should be the difference value that the original clearance of bearing minus the above mentioned two reductions of the radial clearance.